Key Concepts Influencing the Future of Limit Switches for Automated Production Lines

During the period of Industry 4.0, Technological advances in automation production lines have been pivotal in driving precision, safety, and operational efficiency for the entire machine. Limit switches, which are frequently disregarded, serve as critical detection mechanisms in a wide range of industrial operations. They are also termed as switch sensors and serve the purpose of detecting the presence or position of objects, starting machines, and safeguarding them from damages.

As complex automation is adopted by industries, the use of limit switches has changed, enhancing advances in smart manufacturing. Limit switch suppliers are competing and improving with the availability of logic controllers, and industrial Ethernet which adds to the network of smart tools needed for advanced manufacturing. In this case, lld opto electronics also benefit the entire ecosystem of smart manufacturing due to advances in power like wholesale LED power supply.

This paper examines the key innovation areas which affect the future of limit switches while providing automation solutions to increase performance and competitiveness.

Merging with Smart IoT Integrated Systems for Industrial Manufacturing

The most notable advancement in automation technology is perhaps the combination of mechanical systems with digital logic. Everything gets upgraded and even limit switches have not been left out. Modern limit switches are incorporated into the Industrial Internet of Things (IIOT) ecosystems for real-time data, predictive maintenance notifications, and enhanced analytics.

Smart models now incorporate microcontrollers and communication modules with smart limit switches, such as Ethernet/IP and IO-Link, significantly improving the functionality of these devices. Limit switches no longer have to rely on central monitoring systems to receive signals; they can actively report and improve monitoring operations adding a new level of intelligence to basic tasks and aiding production teams.

These switches integrate and operate with sensors and actuators alongside wholesale led power supply systems to construct a finely interconnected control and power efficiency system in highly automated settings.

Emphasis on Compact and Smaller Designs

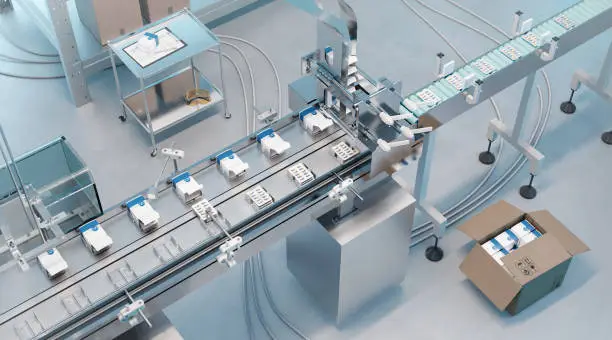

The increasing shift towards Modular Factory Layouts (MFLP) has proven to be an advantage for less performing components that need to be lighter and smaller in size. These compact factories also require multifunctional components. Meeting the innovations constraints put forth by modern factories, compact design and ultra-small autonomous limit switches with flexible mounting and multi-type (roller lever, plunger) or actuators have been invented by manufacturers.

These new designs are particularly beneficial for automated robotic arms, pick-and-place machines, and small CNC equipment. Even at a smaller size, they are engineered to endure severe conditions like vibration, moisture, and high-speed impact.

The addition of miniature components, such as wholesale LED power supply, integrated into the low-voltage power supply units also showcases the trend toward miniaturization. All of these innovations, individually or collectively, enable cavity-efficient designs while retaining intended purpose.

Enhanced Durability for Harsh Environments

For Industrial applications, production lines run in extreme conditions like high temperatures, harsh mechanical loads, and corrosive chemicals. To withstand those challenges, limit switch manufacturers are adopting modern materials: stainless steel, reinforced polycarbonate, and glass sealed boxes.

Replacing traditional materials allows the switches to endure a harsher environment. For production lines with higher throughput, the reduction in maintenance cycles greatly improves overall efficiency. Limit switches with IP67 rating or higher are standard nowadays and allow full protection from dust and water.

In addition to those conditions, the switches are now being certified under international safety standards ATEX and IECEx, making them suitable for use in explosive or high-temperature environments, alongside sustaining integration with global industrial infrastructure.

For regions where both limit switches and wholesale LED power supply modules are subjected to variable temperature and humidity, the switch’s increased durability offers valuable savings in operational costs.

Custom Limit Configuration and Modular Customization

The increased specialization of assembly lines often renders many components inadequate for purchase as they do not suit specific operational needs. Many manufacturers have now developed modular limit switches that can be customized by type of actuator, contact layout, mounting style, and communication protocols.

OEMs and system integrators are now able to modify switch performance tailored to the specific requirements of their machinery like robotic welding stations or high-speed packaging lines.

Customization is also being reflected in power supply systems, where wholesale LED power supplies provide diverse voltage outputs, dimming options, and IP rating selections intended for different factory settings. The ability to choose suitable parts from different domains within automation and power domains enhances efficiency in design and deployment for automation solutions.

Wireless and Contactless Limit Switches

The integration of robotics, rotating equipment, and mobile robotic systems makes wireless and contactless limit switches the most innovative measure and one with the potentially biggest impact. These mechanisms do not require wires, mechanical alterations, or any contact, making them perfect for use in rotating machinery.

Contactless limit switches that utilize RFID, optical detection, and magnetoresistive sensing have many advantages including:

- A lack of physical touch reduces mechanical damage to none

- Increased ease of installation

- Any exposure to dangerous environments is safer for working personnel.

The communication capabilities of these models are suitable for IIoT platforms because they are wireless. Their batteries are frequently long-lasting and can be powered through wholesale LED power supply modules with energy harvesting systems.

Wireless and contactless switches may currently be more expensive than traditional models, but they are anticipated to become more popular as production lines require more flexibility, lower maintenance, and greater demand.

READ MORE : HOW CONVENIENT IS THE FURNITURE IN YOUR RESTAURANT FOR THE GUESTS?

The Connection Between Limit Switches And Power Supply Systems

The relationship between limit switches and power systems is just as important as any other relation in automation. With industrial lines relying more on real time data and precision control, the power stability and power efficiency have become crucial now more than ever.

Most modern control, sensor or switch systems that are not only for lighting but also for controlling voltage and current, use wholesale LED power supply. One important advance is the active smart power supplies that check and control the voltage loads on the provided substation and can relay faulty conditions to preempt equipment failure.

In an example, wholesale LED power supply and limit switch manufacturers came together to create a fault tolerant conveyor belt system. With this system, there were multiple safes put on the overheating, overloading, or erratic machine behavior to ensure there would be uninterrupted production.

Such an integrated design has B2B buyers in mind, as they search for system-level functionalities while still valuing the performance of the component individually.

Conclusion

Limit switches are one of the last components to evolve within a smart factory network. Systems are integrating intelligence and compacted size, requiring added robustness and wireless features. These triggers are no longer simple mechanical components, but full-range technology incorporated in smart factories.

For B2B operating in the manufacturing, packaging, logistics, and industrial automation spaces, it is crucial to be ahead of the curve. Whether you are collaborating with system integrators or buying components for an OEM machine, the relationship between limit switch suppliers and LED power supply wholesalers offers new opportunities in efficiency, dependability, and growth.