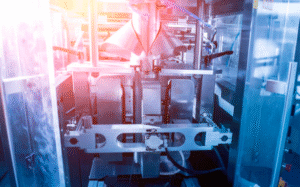

How Capping Machines Improve the Sealing Process in Bottled Products

Among the steps taken in the production process, the packaging process needs to incorporate safety measures for products, especially when it comes to food and drinks. One of the steps that needs particular attention is sealing, which is probably the most important step out of all the packaging steps. Without a proper seal, any and every product can be jeopardized. For packaging food products, capping machines are one of the most important pieces of equipment that have significantly enhanced the sealing process for bottled products. These machines significantly automate the capping process, which improves the speed, accuracy, and consistency of capping on the production line. This article will look at the importance of capping machines and how they impact the efficiency of the entire packaging process.

In Food Packaging, What are Capping Machines?

Capping machines are used for capping different containers ensuring they are airtight to withstand various temperatures, moisture, pressure, or vacuum that is experienced in storage and transportation. In packaged consumables as mentioned before, capping significantly improves and preserves their shelf life as it protects the packed consumable from contamination, leakages, and spoilage. In sectors like food, drinks, medicine and pharmaceuticals, the importance and integrity and safety of the product being sealed makes it paramount that the sealing process is efficient and effective.

A capping machine caps a container by setting the required cap on it, then using pressure or torque to seal the cap tightly enough to secure the contents. Capping machines ease the burden of manual labor so that the operatives can simply set the bottles in the machine and forget about them. With more units produced in a set time frame, they increase profitability. These machines can be incorporated into any packaging operation because they accommodate a wide range of cap types such as screw caps, crown caps, and flip-top caps.

Proper selection of a capping machine is critical in the food packaging industry to ensure that products are appropriately sealed for shipment. A capping machine manufacturer specifically designs this type of equipment for use with other food packing machines, thereby optimizing the entire packaging workflow and increasing productivity.

How Capping Machines Help Improve Sealing Consistency and Precision

One significant advantage of capping machines in bottled product packaging is their enhanced precision and consistency when it comes to the sealing process. In a manual capping process, there is always variability, such as caps being under tightened or over-tightened leading to leakage or quality issues. Capping machines are programmed to provide a sufficient amount of torque every single time, effectively removing these variations and ensuring that caps are properly closed.

Modern capping machines have advanced sensors and torque monitoring systems that detect when a cap has been tightened sufficiently and they guarantee that the caps are put on regardless of the production speed or bottle size. If you are capping smaller quantities of bottles to mass production, capping machines guarantee that every single bottle is sealed which significantly reduces the chances for spoilage or loss.

Capping machines amplify packaging process efficiency and quality by automating and mechanizing parts of the process to a degree not conceivable with manual procedures. Precision is critical in sectors like beverages where products are exposed to oxygen, bacteria, and toxins; this automation ensures there is still consistency and quality.

Safety, Savings, and Long-Term Financial Impact

Capping machines are the unsung heroes behind productive workdays, particularly in high-output production floors. By automating the tedious and laborious manual washing, drying, and capping of bottles, capping machines enable manufacturers to seal hundreds or thousand bottles per hour. The speed at which bottles can be capped is dependent on the automatic capping machines’ rates.

This efficiency not only aids in keeping pace with consumer needs but also eliminates the need for too many employees who would otherwise be needed for manual capping. Since capping machines reduce the needless expenditure on labor, capping machines prove to be profitable. They can also be easily operated without much care which saves money in the long run.

By using capping machines, employees can focus on more specialized tasks like quality control, packaging design, or machine upkeep. They no longer have to engage in mundane manual capping work. Such efficiency allows production lines to run continuously without any breakdowns which, in turn, enhances the rates of production and profits.

Food Safety: Why Proper Seal Bottling is Important

Bottles should be capped properly as this will seal the products inside. This is crucial if there is a need to maintain freshness while also minimizing risk of contamination. If a bottle is poorly sealed, it can leak, aid in the introduction of air, and allow harmful microorganisms, bacteria, or viruses to infiltrate. This along with spoilage can lead to foodborne illnesses that can ruin a brand’s image and destroy customer trust.

Food and beverage products are better protected with capped bottles as these products are more sensitive. Bottles made from glass, plastic, or metal can be packaged using these machines as they provide a tight seal. This ensures that perishables, which have a shorter expiry date, are best used when shielded from the environment for a longer time, such as juices, dairy products and sauces.

Properly sealed bottles not only prevent contamination, but also ensure that carbonation is retained in the beverage. A tight seal ensures that the internal pressure of the bottle stays intact, enhancing the quality and taste. Due to these reasons, capping machines have become essential in the food packaging process, especially for goods that require freshness and quality for customer satisfaction.

Conclusion

Capping machines are an integral part of food packing equipment and help in the sealing process for bottled goods. Capping machines enhance the speed of production, lessen the manual labor expense, improve the consistency of the seals, and magnify food safety. By automating the sealing process, these machines make certain that accurate seal applications are dispensed, which is crucial for the integrity, freshness, and quality of the product.

Capping machine manufacturers offer tailor-made solutions to help fully automate the packaging process, improve productivity, and cope with challenging market requirements. Due to their flexibility, precision, and economical capping machines have become essential for considerable use in the food and drink sector, making certain that the products are properly sealed and preserved. For manufacturers trying to improve their packaging process and remain effective within a dynamic sector, buying reliable capping machines is a wise decision.

also read: What to Wear to a Boho-Themed Wedding or Event in Australia