Conveyor Belt Drive Components: The Shift Towards Modular and Flexible Systems

Conveyor belt systems have long been an integral part of the manufacturing, logistics, and food processing industries. As technology continues to evolve, so do the components that drive these systems. One of the most notable shifts in recent years has been the move towards modular and flexible conveyor belt drive components. This evolution is driven by the need for improved efficiency, reduced downtime, and the ability to quickly adapt to changing operational requirements.

Understanding Conveyor Belt Drive Components

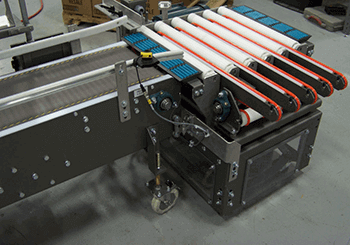

Conveyor belt drive components are the essential elements that power and control conveyor systems. These components include motors, pulleys, bearings, gearboxes, and drive belts. Each plays a crucial role in ensuring smooth and reliable operation. Traditionally, conveyor belt drive components were designed as fixed systems, requiring extensive modifications when changes were needed. However, modern industrial demands have led to a shift towards modular and flexible systems, offering significant advantages in adaptability and efficiency.

The Rise of Modular Drive Systems

Modular conveyor belt drive components are designed with flexibility in mind. Unlike traditional drive systems, which require extensive reconfiguration for any adjustments, modular components allow for easy replacement, upgrades, and reconfiguration. This is particularly beneficial in industries where production demands frequently change or where conveyor layouts must be altered to accommodate new processes.

One key advantage of modular drive systems is the ability to quickly swap out faulty or worn-out components without the need for extensive downtime. For example, modular motorized pulleys can be easily replaced without dismantling the entire conveyor system. This reduces operational disruptions and maintenance costs while improving overall system reliability.

Flexible Conveyor Systems: The Future of Material Handling

Flexibility in conveyor belt drive components is becoming increasingly important as industries seek ways to improve efficiency and adaptability. Flexible drive systems allow manufacturers to customize conveyor configurations based on specific production needs. These systems can be adjusted for speed, load capacity, and direction with minimal modifications.

Advancements in variable frequency drives (VFDs) have played a significant role in enhancing the flexibility of conveyor belt drive components. VFDs enable operators to adjust motor speeds and torque dynamically, ensuring optimal performance based on real-time requirements. This adaptability not only improves efficiency but also extends the lifespan of conveyor components by reducing mechanical strain.

Benefits of Modular and Flexible Drive Components

The shift towards modular and flexible conveyor belt drive components offers several advantages:

- Reduced Downtime: Modular components can be quickly replaced or upgraded without extensive system modifications, leading to minimal operational interruptions.

- Improved Scalability: Flexible drive systems allow businesses to scale operations up or down as needed without major investments in new equipment.

- Cost Savings: The ability to replace individual components rather than entire systems results in lower maintenance and replacement costs.

- Enhanced Energy Efficiency: Modern modular drive systems often incorporate energy-efficient motors and control mechanisms, reducing power consumption.

- Better Customization: Flexible drive components provide greater control over conveyor speed, load capacity, and configuration, allowing for tailored solutions based on specific industry needs.

Applications of Modular and Flexible Drive Components

Industries that benefit from modular and flexible conveyor belt drive components include food processing, automotive manufacturing, e-commerce, and pharmaceuticals. In food processing, for example, hygiene and efficiency are top priorities. Modular conveyor belt drive components allow for easy cleaning and maintenance, ensuring compliance with strict sanitary standards. In e-commerce fulfillment centers, flexible drive systems enable rapid reconfiguration of conveyor layouts to accommodate fluctuating order volumes.

Challenges and Considerations

While modular and flexible conveyor belt drive components offer numerous benefits, there are some challenges to consider. Initial investment costs for modular drive systems may be higher than traditional fixed systems.

Another consideration is compatibility. Not all modular components are universally interchangeable, and businesses must ensure that their chosen drive components are compatible with existing conveyor systems. Proper planning and expert consultation can help mitigate these challenges and ensure a seamless transition to modular and flexible systems.

The Future of Conveyor Belt Drive Components

As industries continue to demand greater efficiency and adaptability, the trend toward modular and flexible conveyor belt drive components will only grow stronger. Emerging technologies such as smart sensors and predictive maintenance systems are further enhancing the capabilities of modern conveyor drive components. These innovations allow businesses to monitor component performance in real time, detect potential issues before they lead to failures, and optimize maintenance schedules for maximum efficiency.

Additionally, advancements in materials science are leading to the development of more durable and lightweight conveyor belt drive components. These improvements contribute to longer operational lifespans and reduced energy consumption, aligning with sustainability initiatives across various industries.

Conclusion

The evolution of conveyor belt drive components toward modular and flexible systems is transforming material handling across multiple industries. By adopting these advanced drive systems, businesses can achieve improved efficiency, reduced downtime, and greater adaptability to changing production needs. As technology continues to progress, companies that invest in innovative conveyor solutions will gain a competitive edge in their respective markets.

For industry leaders seeking high-quality and reliable conveyor belt solutions, Wirebelt offers a range of advanced conveyor components designed to meet the demands of modern manufacturing and processing environments. Their commitment to innovation and quality ensures that businesses can optimize their operations with cutting-edge conveyor belt drive components.

Also read: MVP as a Service: